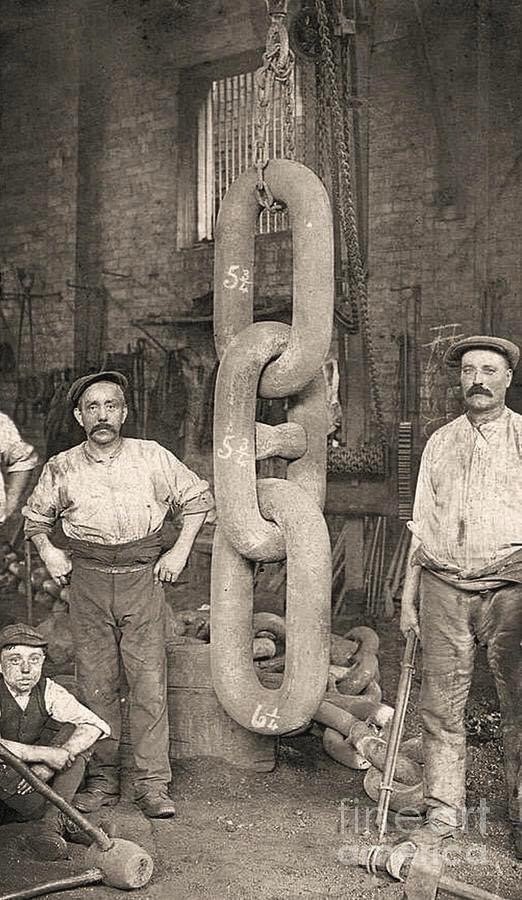

The RMS Titanic, a marvel of early 20th-century engineering, is remembered for its grandeur and tragic fate. However, a lesser-known yet equally fascinating aspect of its construction is the making of its anchor chain at Hingley & Sons in 1909. This process was a testament to the industrial capabilities and craftsmanship of the era.

Hingley & Sons: Masters of Ironwork

Hingley & Sons, renowned for their expertise in ironwork, played a crucial role in the Titanic’s construction. The creation of the anchor chain, a critical component for any vessel, was a task that required precision and skill. The chain, designed to withstand the harsh conditions of the Atlantic, was a product of advanced metallurgical processes of the time.

The Anchor Chain: A Symbol of Strength and Reliability

The anchor chain of the Titanic was not just a functional item; it symbolized the strength and reliability that the ship was meant to embody. Each link in the chain was meticulously forged, ensuring that it could hold the massive anchors of the Titanic, which were essential for the safety and stability of the ship.

The Legacy of the Titanic’s Anchor Chain

Today, the story of the Titanic’s anchor chain serves as a reminder of the industrial prowess of the early 20th century. It highlights the attention to detail and the level of craftsmanship that went into building what was then the world’s largest and most luxurious passenger liner.

Remembering the Artisans Behind the Titanic

While the Titanic is often remembered for its opulence and its tragic sinking, the story of its anchor chain reminds us of the skilled workers and artisans like those at Hingley & Sons. Their work, though less celebrated, was vital in the making of this historic ship. The anchor chain of the Titanic stands as a testament to their skill and dedication to quality.

Q: How large was the Titanic’s anchor chain?

A: The Titanic’s anchor chain was massive, reflecting the overall size of the ship. Each link in the chain was substantial, designed to handle the weight of the Titanic’s anchors, which were among the largest ever constructed at the time. The exact dimensions of each link and the total length of the chain were a testament to the engineering feats of the era.

Q: What was the process of making the anchor chain?

A: The process of making the Titanic’s anchor chain involved several steps, including forging, shaping, and testing each link. The chain was made from high-quality iron or steel, and each link was carefully inspected to ensure it met stringent safety standards. The process was labor-intensive and required a high level of skill and precision.

Q: Why was Hingley & Sons chosen to make the Titanic’s anchor chain?

A: Hingley & Sons was chosen for their reputation in ironwork and their proven track record of producing high-quality chains for large ships. Their expertise in metallurgy and their ability to handle large-scale projects made them an ideal choice for the Titanic, which required the best materials and craftsmanship available at the time.

Q: Is any part of the Titanic’s anchor chain preserved today?

A: Pieces of the Titanic, including parts of its anchor chain, have been recovered and preserved. These artifacts are often displayed in museums and exhibitions dedicated to the Titanic, offering a tangible connection to the ship’s history and the industrial era in which it was built.

Q: What does the anchor chain tell us about the Titanic’s construction?

A: The anchor chain of the Titanic tells us about the meticulous attention to detail and the emphasis on quality and safety in the ship’s construction. It reflects the engineering capabilities of the time and the dedication to creating a vessel that was not only luxurious but also reliable and sturdy.

As an Amazon Associate we earn from qualifying purchases through some links in our articles.